OUR STORY

ALPHA INNOVATION CO., LTD. have been a leading manufacturer of fiberglass canopies and 4x4 accessories since 1982 under the trademark of ALPHA. We are the only company in Thailand to manufacture a complete canopy, which means that we not only produce the shell of the fibreglass canopy, but other parts such as metal parts and glasses are also made in-house. By doing this we are able to control and maintain the highest level of product quality. The secret of our success is we use high quality materials and a wealth knowledge and experience to develop new products and we never stop designing or improving.

At ALPHA, we operate from a 13,100 square meter factory located in Samutprakan, Thailand. We have a vast international presence with the factory based in Thailand and an export network that extends through more than 50 countries around the globe. From the very beginning, our philosophy has never altered from its original course of design, quality, durability and reliability.

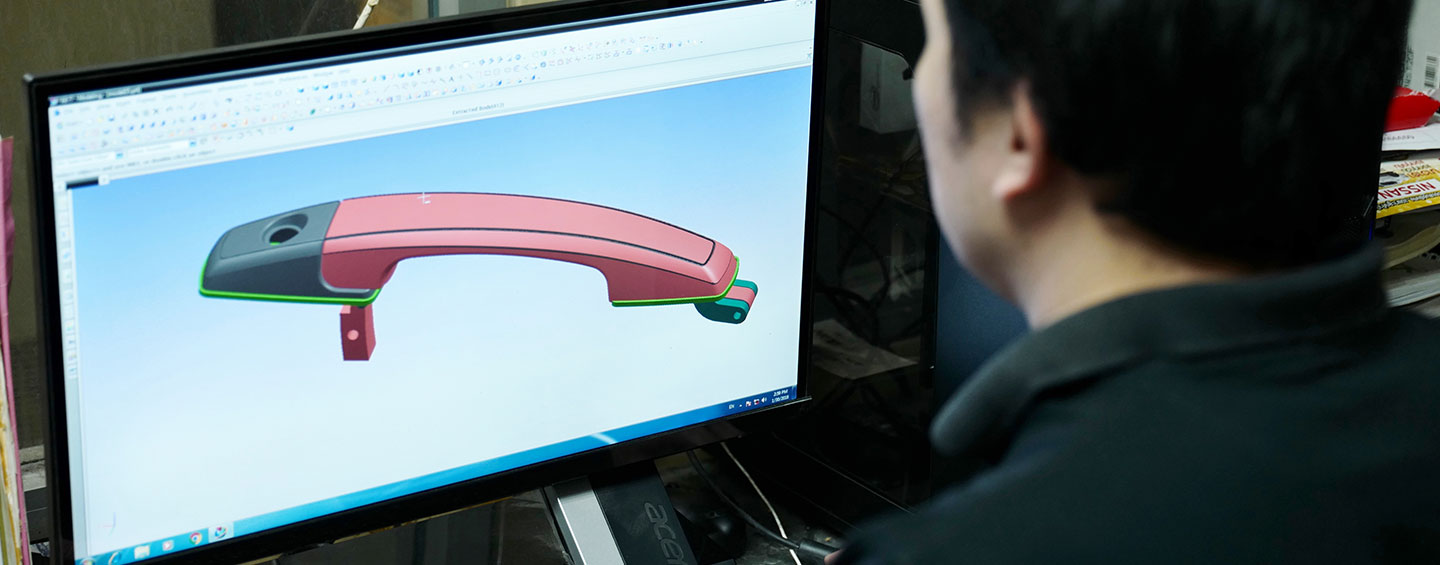

OUR RESEARCH & DEVELOPMENT

At Alpha we place great emphasis on research and development because we believe that this plays a very important role in quality and functions of the final product. We feel R&D provides a platform for creativity and innovation to grow and ensure that our products meet our customer’s satisfaction.

Each and every product’s master model is shaped and styled by the hand of our master craftsmen. All parts are designed in-house, which allows us to better understand the functions and mechanics of the part, and continues to improve. Moreover, constant product testing on all parts ensures greater strength and a longer life.

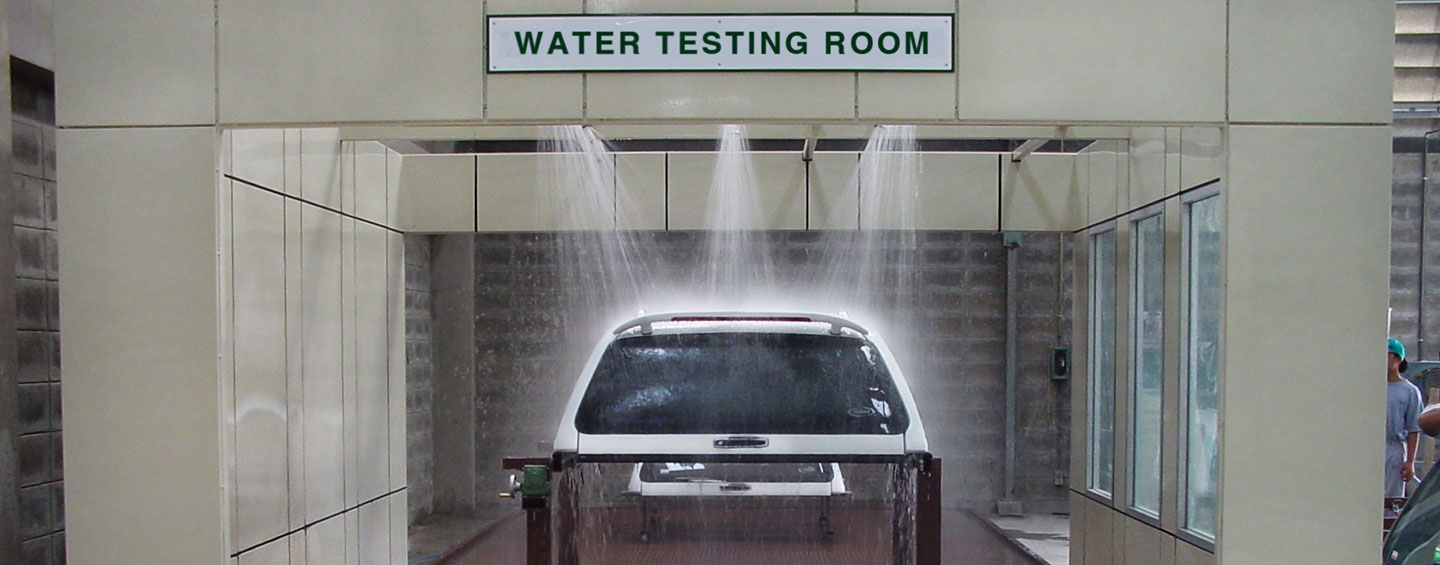

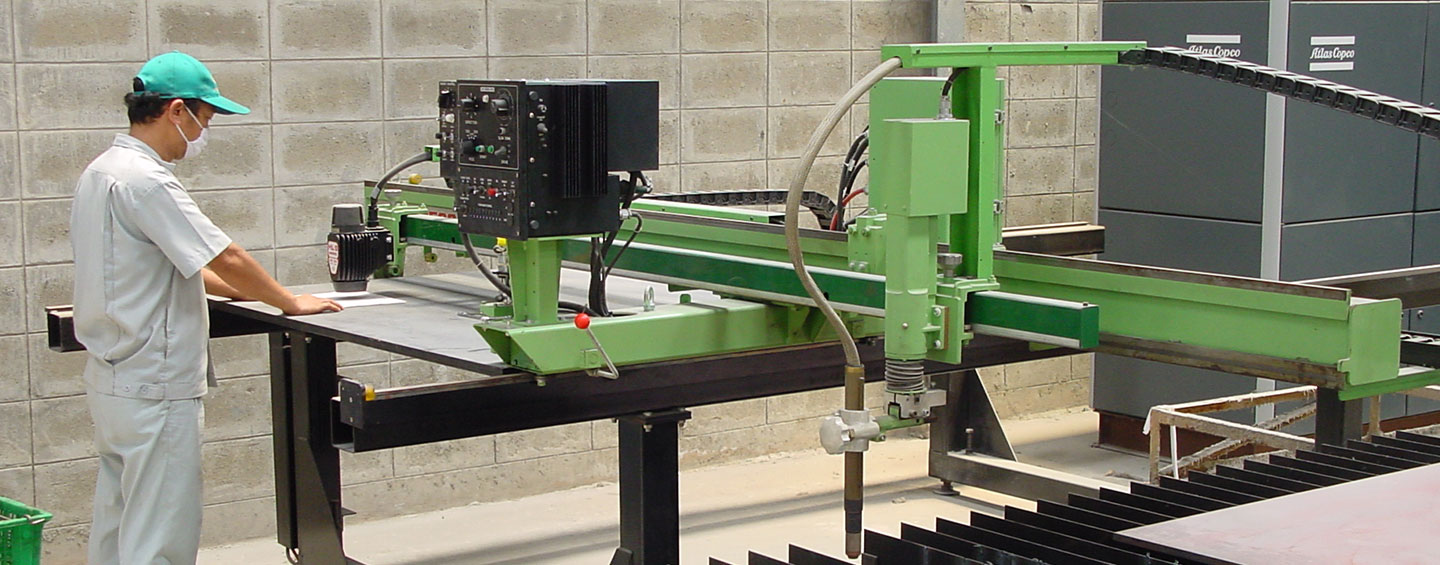

OUR MANUFACTURING

Alpha continues to maintain its position as a leading manufacturer of fiberglass canopies and 4x4 accessories by utilizing the most innovative, advanced equipment and machinery.

At Alpha, the fiberglass shells of the canopies are made by hand and this requires a skilful and highly trained work force. However, when it comes to metal parts and glasses, these are produced using the most advanced level machinery and instruments in every process.

As the majority of our machines are run using CNC, the finished parts are consistent in their dimensions and specifications, leading to a better fit and smoother function of the parts on the canopy. Our specialists are assigned to supervise and monitor each department closely to help in underlining the production standards and ensuring that the quality of the products meets our customer’s expectations.

OUR DISTRIBUTION

Finished products are stored at Alpha’s factory and shipped out to over 50 countries worldwide. Each product is packed in a cardboard box with a wooden pallet to protect against any damages that could possibly happen in the shipping process.

Our professional loading team is set up to calculate the optimal loading capacity of each container and ensure that the products are loaded securely and safely into the container.